With the continued advancement of technology, gone are the days when fixing pipes would take ages to complete and cause major disturbance to the surrounding areas. Especially when it comes to industrial pipe repair, Dallas, Texas, many prefer the so-called trenchless pipelining or the technique of creating a pipe within a pipe.

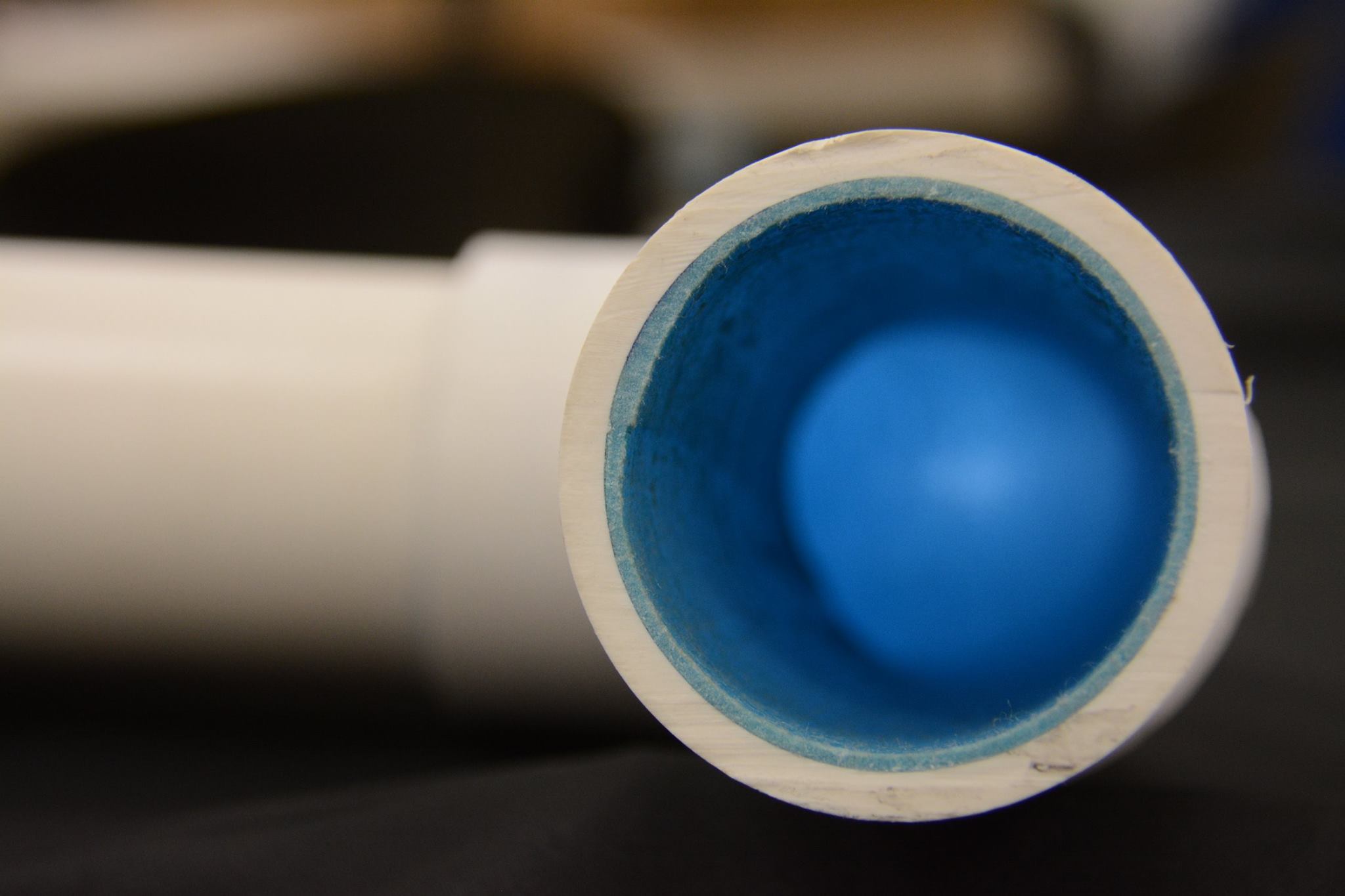

In a nutshell, this repair method involves installing and inflating a pipe liner (a flexible tube typically coated by epoxy or resin) within a damaged pipe. Because the new pipe created is corrosion resistant and jointless, it is hailed for its durability. But how long does an epoxy pipe lining really last?

On average, this kind of lining can last for four to five decades. However, it is important to note that the average warranty for epoxy itself is at five to 10 years. The longevity of the epoxy depends if the pipe lining was done properly.

How Pipelining Works

Professionals who offer services like industrial pipe repair, Dallas, Texas, know how vital it is to properly accomplish every phase of the pipelining method. To give you a better picture of how it’s done, here’s the step-by-step procedure:

Inspection of the pipe involved with the use of cameras in order to confirm the location of the cracks/corrosion

Cleaning of the damaged pipe and removal of any blockages that may hinder the efficient installation of the new pipe

Measurement of the damaged pipe

Preparation of the pipe liner

Saturation of the pipe liner with epoxy and inverting it so that the epoxy will be the one on the exterior of the tubing (this way, it will be able to perform its adhesive function)

Insertion of the inverted pipe liner to the compromised pipe

Blowing of compressed air to push the pipe liner against the interior walls of the damaged pipe

Allowing the epoxy to dry and harden to create a solid pipe within the old pipe (this may take two to five hours)

Restoration of services to the pipe

As mentioned, there’s an average warranty of five to 10 years for the epoxy used in the pipelining technique (may it be residential, commercial, or industrial pipe repair Dallas, Texas). This is an added measure in case the adhesion process wasn’t done properly — the consequence of which is that the epoxy liner can become unstable and may slip some time in the future.

Maintaining Your New Pipe

To maximize the lifespan of an epoxy pipe lining, regular maintenance and inspection are needed. This involves drain cleaning, sewer camera inspections, and regular replacement of joints and addressing of leaks and other damages.

It will also be beneficial if you have an eco-friendly home. The presence of various chemicals in the products you use in your household (which can find its way to your pipes through wastewater) can contribute to the corrosion and premature wearing of your pipes.

To give proper attention and care to your piping system, it’s highly recommended to seek help from the experts. Apart from having appropriate tools, they can also give your professional advice about the condition of your pipes and the most cost-effective way of addressing any damage.

If you need help with industrial pipe repair, Dallas, Texas, contact Advanced Pipe Repair today. We provide efficient service and solutions to help solve your problems.